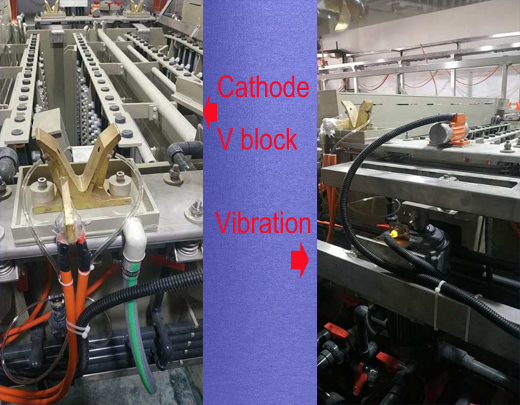

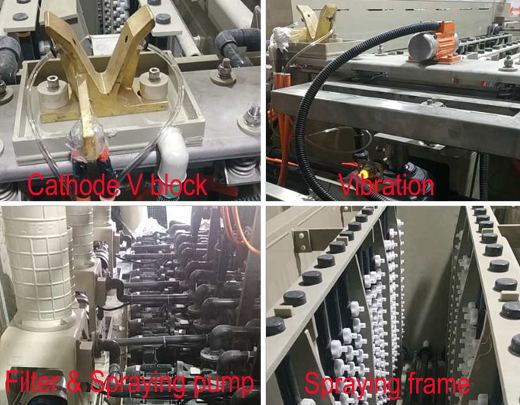

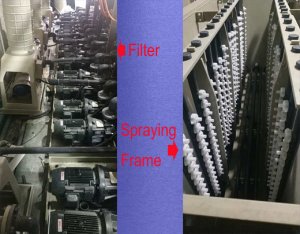

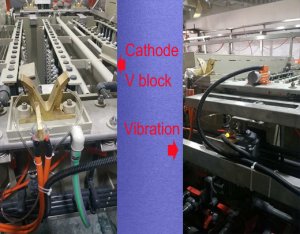

The founction of copper plating line is thicken the copper layer in the panel surface and conductivity holes. The panels themselves act as cathodes for electroplating and we can plate the hole walls thanks to the conductive carbon layer or thin copper layer already deposited there. The operator starts the automated plating line. The copper surface of the panels is cleaned and activated in a number of baths and then electroplated. . The whole process is computer controlled to ensure that each set or flight of panels stays in each bath exactly the right amount of time.

Product Description

The founction of copper plating line is thicken the copper layer in the panel surface and conductivity holes. The panels themselves act as cathodes for electroplating and we can plate the hole walls thanks to the conductive carbon layer or thin copper layer already deposited there. The operator starts the automated plating line. The copper surface of the panels is cleaned and activated in a number of baths and then electroplated. . The whole process is computer controlled to ensure that each set or flight of panels stays in each bath exactly the right amount of time.

Working process : Acid dipping → Degreasing → Double Rinsing → Micro-etch → Double rinsing → Acid rinsing → Copper plating line →Double Rinsing → Acid-dipping→ Tin plating → Double rinsing → Cool drying → Hot drying → Discharge

Product Features

- The main parts are word or China famous brand.

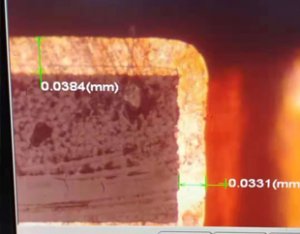

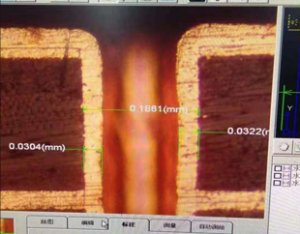

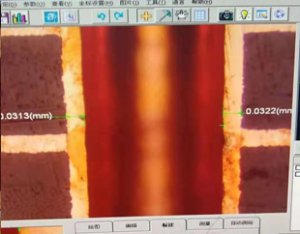

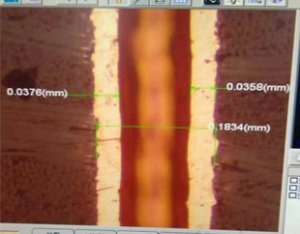

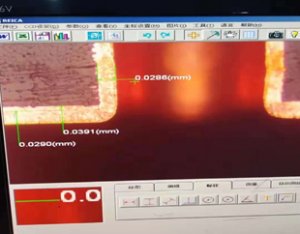

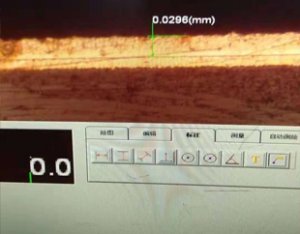

- The aspect ratio can reach 20:1.

- Min hole can be 0.15mm.

- Can plating filling holes.

- Test data: Aspect ratio: 20:1; Panel thickness: 4mm, Result: TP110

Looking forward to providing you with satisfactory products and services.

info@everest-machinery.com