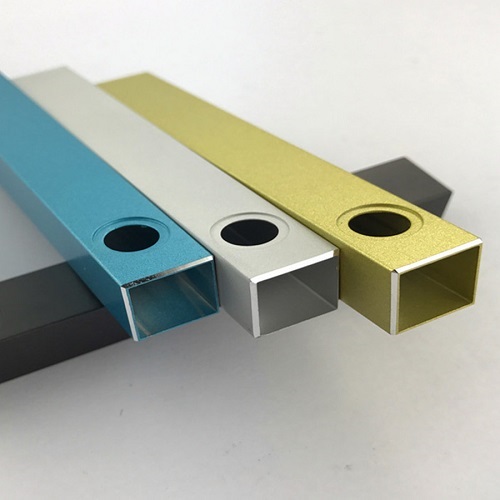

What’s the difference between the anodizing and Conductive oxide ?

Different production processes

Anodizing is the process of forming an oxide film on aluminum products (anodes) under the action of external current.

Chemical conductive oxidation (also known as chemical oxidation) actually does not need to be powered on. It only needs to be soaked in solution. It is a pure chemical reaction.

Production time

Anodizing takes a long time, and the production process takes dozens of minutes.

The production process of chemical conductive oxidation takes a very short time, which can be completed in a few seconds.

Wear resistance

The anodic oxidation film has several microns to dozens of microns, has good hardness and wear resistance, and can be used in the production of kitchenware and other daily necessities.

The thickness of the oxidation film of chemical conductive oxidation is thin, about 0.01-0.15㎛, and the wear resistance is poor.

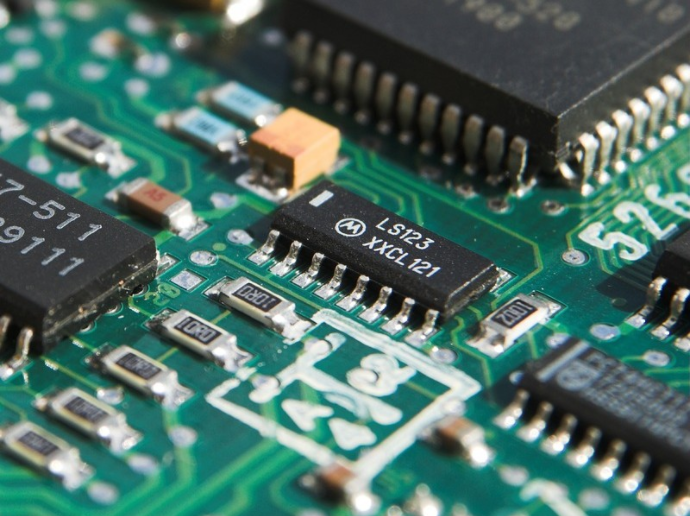

Different conductivity

The film formed by anodizing has good insulation performance.

Aluminum parts have certain corrosion resistance and conductivity after chemical conductive oxidation. In electronic equipment, aluminum parts can prevent electromagnetic signal interference after chemical conductive oxidation.

Different scope of application

Anodizing has poor anodizing effect on cast aluminum and is not suitable for aluminum products with complex shapes.

Chemically conductive oxidation can be used for deformed aluminum electrical parts and for larger parts or assemblies that are not suitable for anodizing.

Jul. 17, 2020

Jul. 17, 2020