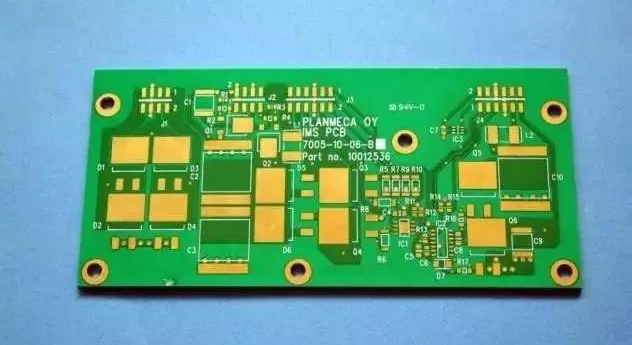

Gold plated board and gold-plated board are commonly used processes for PCB circuit boards. Many engineers can not correctly distinguish the differences between the two. Some engineers even think that there is no difference between the two. This is a very wrong view and must be corrected in time.So what impact will these two “gold boards” have on circuit boards?Now I’ll explain it to you in detail to help you understand the concept thoroughly.

What is gold plating?

The whole plate gold plating generally refers to “electrodeposited gold”, “electrodeposited nickel gold plate”, “electrolytic gold”, “electrodeposited gold” and “electrodeposited nickel gold plate”. There is a distinction between soft gold and hard gold (generally hard gold is used for gold fingers). The principle is to dissolve nickel and gold (commonly known as gold salt) in chemical medicine water,The circuit board is immersed in the electroplating cylinder and connected with current to generate nickel gold coating on the copper foil surface of the circuit board. Electroplated nickel gold is widely used in electronic products because of its high hardness, wear resistance and not easy to oxidize.

What is immersion gold?

Gold immersion is to generate a layer of coating through chemical redox reaction. Generally, the thickness is thicker. It is one of the deposition methods of chemical nickel gold layer, which can achieve a thicker gold layer.

Difference between gold plated and gold plated circuit boards

1.Generally, the thickness of gold deposit is much thicker than that of gold plating. The gold deposit will be golden yellow, which is more yellow than that of gold plating. Customers are more satisfied with the gold deposit on the surface.The crystal structures formed by the two are different.

2.Due to the different crystal structure formed by gold deposition and gold plating, gold deposition is easier to weld than gold plating, which will not cause poor welding and cause customer complaints.At the same time, because gold is softer than gold plating, gold finger plate is generally gold plating, hard gold is wear-resistant.

3.Only the pad of the gold sinking plate has nickel gold. In the skin effect, the signal transmission is in the copper layer, which will not affect the signal.

4.Compared with gold plating, gold precipitation has a denser crystal structure and is not easy to produce oxidation.

5.With the increasingly dense wiring, the line width and spacing have reached 3-4mil.Gold plating is easy to produce gold wire short circuit.There is only nickel gold on the pad of the gold sinking plate, so it will not produce gold wire short circuit.

6.Only the pad of the gold sinking plate has nickel gold, so the combination of resistance welding and copper layer on the circuit is more firm.The project will not affect the spacing when making compensation.

7.It is generally used for boards with relatively high requirements and good flatness. Generally, gold sinking is used. Generally, there will be no black pad after assembly.The flatness and service life of the gold-plated plate are as good as those of the gold-plated plate.

The above is the difference between the gold-plated plate and the gold-plated plate. At present, the price of gold on the market is expensive. In order to save costs, many manufacturers are unwilling to produce the gold-plated plate, but only make the gold-plated plate with nickel on the pad, which is really much cheaper in price.I hope this introduction can provide you with reference and help.

1.Gold sinking plate and chemical gold plate are the same process products, and electric gold plate and flash gold plate are also the same process products. In fact, they are just different names for different people in the PCB industry. Gold sinking plate and electric gold plate are mostly called by their counterparts in the mainland, while chemical gold plate and flash gold plate are mostly called by their counterparts in Taiwan.

2.Generally, the gold deposition plate / gold chemical plate is formally called chemical nickel gold plate or nickel chemical gold leaching plate. The growth of nickel / gold layer is plated by chemical deposition;Gold electro gold plate / flash gold plate is generally formally called nickel gold plate or Flash gold plate. The growth of nickel / gold layer is plated by DC plating.

3.The following table for the mechanism difference between chemical nickel gold) and electroplated nickel gold plate (gold plating):

|

Electroless Nickel Immersion gold |

Ni/Au Plating |

|

Now the bare copper surface of the circuit board is reactive deposited to form a nickel coating containing 7-9% phosphorus, with a thickness of about 3-4um, and then a pure gold layer with a thickness of about 0.05-0.15um is replaced on the nickel surface. |

Electroplating copper / nickel / gold coating on the bare copper surface of the circuit board, with nickel layer of about 4-8um and gold layer of about 1-3um |

Differences in characteristics between gold-plated plate and gold-plated plate:

|

Surface coating /properties |

appearance |

Weldability |

signal transmission |

quality |

engineering |

|

Gold plating plate |

Golden white |

Generally, there is occasional poor welding |

Skin effect is not conducive to the transmission of high-frequency signals |

1. Gold surface is easy to oxidize 2. It is easy to cause the gold wire to be slightly short 3. The bonding force of resistance welding is not strong |

Linewidth compensation, Influence spacing |

|

Gold immersion plate |

Golden yellow |

Good |

Influence of skin effect on high frequency signal transmission |

1. Not easy to oxidize 2. No gold wire 3.Resistance welding has good adhesion |

Linewidth compensation, Does not affect spacing |

Why don’t you usually “spray tin”?

With the increasing integration of IC, the IC pins are more and more dense.The vertical tin spraying process is difficult to smooth the fine solder pad, which brings difficulty to SMT mounting;In addition, the shell life of the tin spray plate is very short.The gold-plated plate solves these problems:

1.For the surface mount process, especially for 0603 and 0402 ultra small surface mount, because the flatness of the pad is directly related to the quality of the solder paste printing process and has a decisive impact on the subsequent reflow welding quality, the whole plate gold plating is often seen in the high-density and ultra small surface mount process.

2.In the trial production stage, affected by factors such as component procurement, it is often not that the board is welded immediately when it comes, but it often has to wait for several weeks or even months to use. The shelf life of the gold-plated board is many times longer than that of the lead tin alloy, so everyone is willing to use it. In addition, the cost of the gold-plated PCB in the sampling stage is almost the same as that of the lead tin alloy board.However, with the increasingly dense wiring, the line width and spacing have reached 3-4mil.Therefore, the problem of gold wire short circuit is brought:

With the increasing frequency of signal, the influence of signal transmission in multi coating due to skin effect on signal quality is more and more obvious.

Gold 0.003mil; resistivity: 2.4

Nickel 0.150mil; resistivity: 6.9

Copper 1.4 mil; resistivity: 1.72

Skin effect refers to the high-frequency alternating current, which tends to concentrate on the surface of the conductor.According to the calculation, the skin depth is related to the frequency:

|

Frequency (Hz) |

Depth (MIL) |

Frequency (Hz) |

Depth (MIL) |

Frequency (Hz) |

Depth (MIL) |

|

60 |

8.6 |

100 |

6.6 |

1K |

2.1 |

|

10k |

0.66 |

100k |

0.21 |

1M |

0.066 |

|

10m |

0.021 |

100M |

0.0066 |

1G |

0.0021 |

Other disadvantages of gold-plated plate are listed in the difference table between gold-plated plate and gold-plated plate.

Why choose gold-plated plate instead of gold-plated plate?

In order to solve the above problems of gold-plated board, the PCB with gold-plated board mainly has the following characteristics:

1.Because the crystal structure formed by gold precipitation and gold plating is different, the gold precipitation will be golden yellow, which is more yellow than gold plating, and the customer is more satisfied.

2.Because the crystal structure formed by gold deposition and gold plating is different, gold deposition is easier to weld than gold plating, which will not cause poor welding and cause customer complaints.

3.Because only nickel gold is on the pad of the gold sinking plate, the signal transmission in the skin effect is in the copper layer, which will not affect the signal.

4.Because the crystal structure of gold precipitation is more dense than gold plating, it is not easy to produce oxidation.

5.Because only the pad of the gold sinking plate has nickel gold, it will not produce gold wire and cause micro short.

6.Because only nickel gold is on the pad of the gold sinking plate, the combination of resistance welding and copper layer on the line is more firm.

7.The project will not affect the spacing when making compensation.

8.Because the crystal structure formed by gold precipitation and gold plating is different, the stress of the gold precipitation plate is easier to control, which is more conducive to the processing of bonding products.At the same time, it is precisely because gold sinking is softer than gold plating that gold fingers made of gold sinking plate are not wear-resistant.

9.The flatness and service life of the gold-plated plate are as good as those of the gold-plated plate.

Jul. 23, 2020

Jul. 23, 2020