The shape of the part is determined by the designer according to the needs of the product structure, but the shape of the part often brings many difficult problems to the surface treatment production.

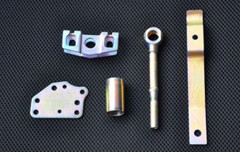

For example, large-area flat parts, formed tubular parts, spherical parts, parts with blind holes or internal threads, parts with edges that are not chamfered or rounded, very light-weight sheet parts, with a very high ratio of bore to length. Small deep-hole parts, tubular parts requiring inner surface plating, parts with a tapered working surface, box-shaped parts, bottle-shaped parts and other complex-shaped parts are surface treated, unless special technical measures are taken. It is difficult to obtain a coating of satisfactory quality on the surface of the part.

The influence of the shape of the part on the quality of electroplating is mainly because it affects the uniformity of the distribution of the electroplating current on the surface of the part. The edge parts and orifice parts on the part are the parts where the current is concentrated. The plating current distributed in these parts may be many times higher than other surfaces. , it is often difficult to introduce electroplating current without the use of auxiliary anodes. It can be seen that when electroplating on the surface of a part with a complex shape, the thickness of the coating on the surface of each part must vary greatly. Even if the plating solution is used with a very good dispersion ability and coverage ability, it is sometimes difficult to overcome the complex shape. impact. Therefore, for the surface of parts with complex shapes, it is not objective to specify the uniformity index of coating thickness or to require all surfaces to be coated. For this reason, electroplating enterprises must coordinate with users the requirements for the coating layer when they encounter the electroplating of parts with complex shapes.

Electroless plating and chemical conversion coating are performed on parts with complex shapes , although the influence of the shape on the uneven thickness of the coating layer is reduced, the solution in the cavity or the deep concave part is difficult to carry out with the main solution in the tank. Exchange, so that the solution at the interface is updated in time, and when the surface of these parts is chemically reacted with the solution, the gas generated is not easy to be discharged to form “air pockets”, which often have adverse effects on the quality of the coating layer. In addition, the parts with complex shapes are also easy to carry the solution, which will be brought along between the processes, resulting in cross-contamination of the solution. Therefore, it is necessary to reserve process holes for the flow and drainage of solutions and gases in parts that do not affect the appearance and use of the parts.

It is also very difficult to coat very light sheet parts, because when the sheet parts are placed in a drum or in a basket for processing, they are easily attracted to each other, preventing normal coating or conversion coating deal with.

Sometimes we encounter such parts, every surface of which is considered to be a working surface, and it is almost impossible to find a suitable position, which can be used as a clamping point for a fixture, which makes electroplating difficult. The designer negotiates the location of the clamping.

Mar. 08, 2022

Mar. 08, 2022