Barrel plating is that the work piece is loaded into the drum, which is suitable for small parts. The number of each barrel is large and the plating thickness is below 10μm.

Barrel plating is another common method in electroplating production.It is a method to place the parts to be plated in a polygonal drum, connect the cathode by relying on the weight of the work piece itself, and realize metal electrodeposition in the process of drum rotation.

Product Description

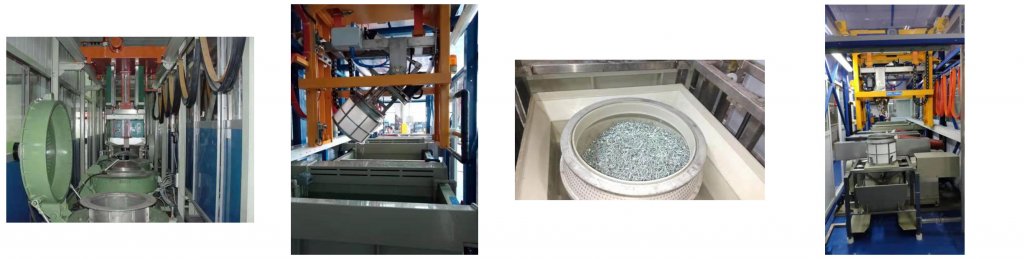

Barrel plating

Barrel plating is that the work piece is loaded into the drum, which is suitable for small parts. The number of each barrel is large and the plating thickness is below 10μm.

Barrel plating is another common method in electroplating production.It is a method to place the parts to be plated in a polygonal drum, connect the cathode by relying on the weight of the work piece itself, and realize metal electrodeposition in the process of drum rotation.

The biggest difference between barrel plating and rack plating of small parts is that it uses a drum, which is a material holding device that carries the plating of small parts in the process of constantly rolling.A typical drum is hexagonal and placed horizontally.One side of the drum wall plate is open. During electroplating, a certain number of small parts are installed into the drum from the opening, and then the drum door is covered to close the opening.There are many small holes on the drum wall plate. During electroplating, the conduction of current between parts and anode, the renewal of solution inside and outside the cylinder and the discharge of waste gas all need to pass through these small holes.The cathode conductive device in the drum passes through the central shaft holes on both sides of the drum through copper wires or rods, and then is respectively fixed on the conductive feet of the left and right wall panels of the drum.The parts are naturally connected with the cathode conductive device by their own gravity in the drum.The barrel plating of small parts is carried out in such a device.Many factors such as the structure, size, rotating speed, conductive mode and hole opening rate of the drum are related to the production efficiency and plating quality of barrel plating.Therefore, roller is one of the key points of the whole barrel plating technology.

Compared with rack plating, the biggest advantages of barrel plating are saving labor, improving productivity, less equipment maintenance cost and small floor area, and good uniformity of plating.

Product Details

Looking forward to providing you with satisfactory products and services.

info@everest-machinery.com